Farapayeh Dalin Co. production lines will be able to supply all types of GRE pipes and fittings according to API 15HR, ISO 14692 and ISIRI 22829 standard requirements from (40 to 600 mm nominal diameter) 1½ to 24 inches , up to (250 bar) 3600 psi working pressure and 135 ° Celsius (275 °F) operating temperature.

It is noteworthy to mention that after years of research, now the entire infrastructure for the design process and qualification tests of the GRE pipes is available in the Faratac Technology Center, one of the most advanced and well-equipped research centers of composite structures in the world, and now these products are ready to be utilized Worldwide in oil and gas industries.

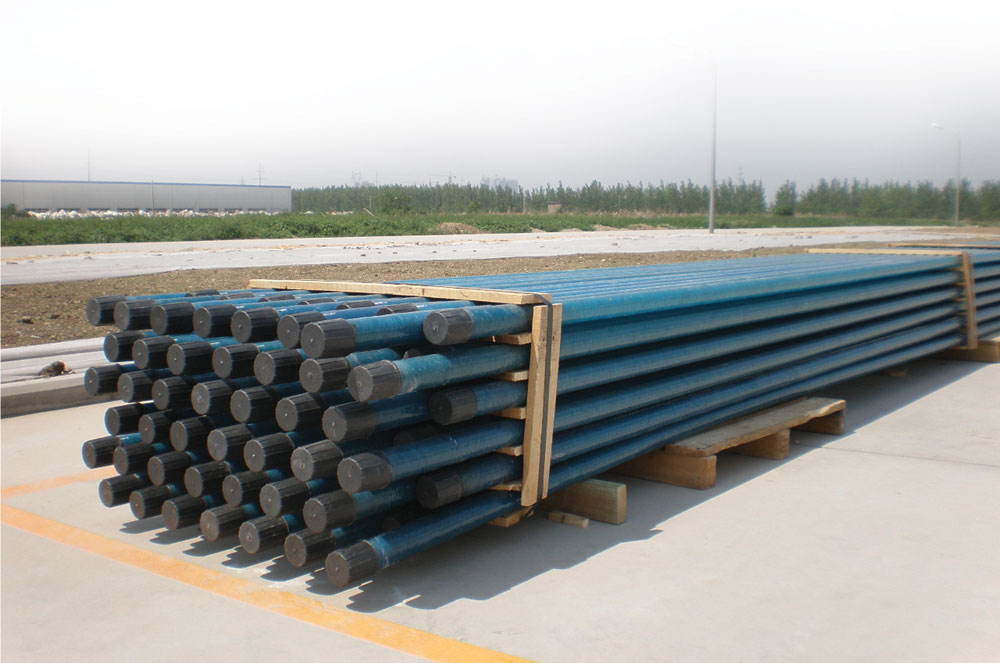

Combining various benefits of having threaded joints, light weight (⅟4 of metallic pipes), high strength, corrosion resistance, extended durability against environmental issues and mechanical loadings, Glass-Fiber Reinforced Epoxy (GRE) pipes are increasingly utilized in the infrastructure industries throughout the world.

Thanks to the design flexibility of composite materials, it is possible to customize the properties of these pipes for various applications. Consequently, they are currently considered as the main competitor of traditional piping systems in the oil, gas and petrochemical industries in the world.

In addition, having threaded joints ensures fast installation with adequate sealing which reduces the time spent on the installation of transmission and process lines.

These products can be designed and produced to have a lifespan of up to 50 years, depending on the needs of our respectful customers.

About Us

Farapayeh Dalin Company has defined its mission as the “Design, production, implementation, and operation of fluid transmission systems using epoxy composite pipes and fittings.” The company strives to achieve its vision: “By 2026, Farapayeh Dalin will be one of the three leading suppliers of GRE (epoxy) pipes in the Middle East.”

To accomplish this, the company adopts global standard requirements such as ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, HSE-MS, and ISO 10002:2018. It continuously identifies, plans, and periodically reviews its processes while focusing on the following:

- Meeting quality management, safety, health, and environmental management standards

- Planning, defining, monitoring, and periodically reviewing organizational objectives

- Developing organizational assets

- Planning, executing, and monitoring improvement projects in all areas with a continuous improvement approach toward sustainable development

- Maximizing efforts to ensure stakeholder satisfaction, especially customers

The sustainable development goals associated with Farapayeh Dalin include economic growth and decent employment, as well as industry, infrastructure, and innovation.

I firmly believe that teamwork, collaboration, and solidarity among esteemed colleagues will enable the organization to achieve its vision.

Therefore, all process owners are expected to align with organizational goals and, within an agile and disciplined framework, effectively engage with the HSEQ system for its implementation, maintenance, periodic review, and continuous improvement.

Mission:

Design, production, implementation, and operation of fluid transmission systems using epoxy composite pipes and fittings.

Vision:

By 2026, Farapayeh Dalin will be one of the three leading suppliers of GRE (epoxy) pipes in the Middle East.

Operational Plan to Achieve the Vision:

- Inclusion in the vendor list of national oil companies by the end of 2023

- Achieving 50% of the nominal production capacity by the end of 2024

- Reaching 75% of the nominal production capacity by the end of 2025

- Attaining full nominal production capacity by the end of 2026

Sustainable Development Goals of Farapayeh Dalin:

- SDG 8: Economic growth and decent jobs

- SDG 9: Industry, infrastructure, and innovation

Committed Values:

- Agility

- Accountability

- Contribution to achieving national self-sufficiency

- Mutual respect

- Environmental protection